Company Profile

Toky Electrical Company: deeply cultivating in the intelligent control instrument industry for more than 30 years, is the high-end temperature control partner of the new generation of industry.

In the field of industrial automation, the selection criteria for engineers and purchasers are being upgraded, what they need is not only functional equipment, but also technical partners that understanding their needs, while easy to operate and highly reliable. Founded in 1992, Guangdong Toky Electrical Co., Ltd. is one of the leading domestic manufacturer of temperature controllers, with the mission of making measurement and control more accurate, reliable and efficient. Devoting in the temperature controller industry for over 30 years, Toky company has established itself as a preferred supplier of domestic temperature control solutions for strategic industries such as new energy, semiconductors, and high-end equipment manufacturing, with its technological innovation, expert product and caring service.

Hard-core technology: use algorithm innovation to break through the pain points of the workshop, and define the strength of domestic high-end brand.

The actual needs of the industrial site are hidden in engineers’ daily life: slow heating of equipment delays production, temperature overshoot leads to material scrap, time-consuming parameter debugging affects efficiency, etc. Toky uses a set of competitive core algorithms to accurately solve these pain points.Toky independently developed ‘TPID’ control algorithm, which is like an AI brain for the temperature control system: the intelligent fuzzy reasoning PID technology, compared to traditional PID, enhances the equipment's heating rate by 30%. The adaptive + self-learning function can automatically match parameters, preventing overshoot fluctuations and material waste. More disruptively, when there is an up and down oscillation, the PID setting time is greatly reduced, making the days of staying up late at midnight to adjust parameters a thing of the past.To tackle the stranglehold issues in high-precision fields such as semiconductors and photovoltaics, Toky has introduced a ‘2-DOF-PID + cascade structure’ control technology, achieving the breakthrough of domestic technology (with performance benchmark to international top brands). Data from a leading semiconductor equipment manufacturer shows that this technology has continuously improved production yields, directly helping it break through the foreign technology blockade. Today, Toky's core algorithm has been deeply applied to the core production lines of BYD, CATL and other industry-leading companies. In high-end scenarios such as new energy lithium battery and semiconductor annealing, it makes engineers' voting with their feet by its technical strength.

Expert product: functional, intuitive, good-looking, precisely fitting the needs of new generation

The new generation's selection logic is the balance between professional performance and user experience. Toky has developed four series of high-precision temperature controllers (from the Flagship 0.05 grade to the economy 0.3 grade) with its quality strategy. These controllers benchmark, or even surpass the precision of imported brands, enable users to choose based on their needs, for a wide range of applications from semiconductor equipment to general industrial production lines, avoiding the cost-inefficiency of ‘big horse pulls small cart’.

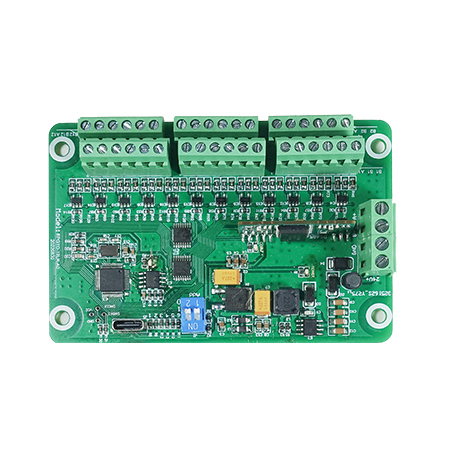

We know the new generation of engineers care more about the ease of use: humanized operation interface + one-click auto-tuning function, enables new engineers to master core operations in just 30 minutes. The intelligent gateway supports direct PLC connection, real-time collection of equipment status and alarm information without the additional programming. An engineer from a plastic machinery factory said: "Previously, collecting data required writing numerous communication commands, but now the efficiency has been at least doubled."

The design is also professional: the ultra-thin blade-type splicing module is suitable for the compact layout of intelligent production lines. A procurement executive of a new energy battery factory admitted: "Installing Toky instrument on the new production line shows a sense of technology more intensely than imported brands, expressing customers deeply when they inspect the factory. "

Reliability: full-cycle guarantee + fast service, builds the cornerstone of trust

Reliability is the core bottom line for customers to choose partners. Toky has built a quality moat with three dimensions of ‘strict standards, complete testing and fast response’.

· Full-cycle testing: equipped with a professional laboratory, covering product performance, EMC electromagnetic compatibility, safety regulations, environmental adaptability (-40℃ extreme cold / 85℃ high temperature test), structural reliability (vibration/impact test) and other full-dimensional testing, Toky fully monitors it from R&D to mass production.

· Authoritative certification: the main products have been certified by UL, CE and other international authorities, The instrument has achieved excellent results in the “10-year life test” item, which is based on the type test, becoming the industry model of reliability with superior performance that ensures the stable use for more than 10 years.

· Fast service: the company has set up over 30 offices across the country, each equipped with a professional service team of front-end sales engineers, providing 7x24 hours local services. A purchaser from a machinery factory recalled: "When the equipment alarmed at 3:00 a.m., Toky’s engineer provided remote guidance and resolved the issue within half an hour, which is more than twice as fast as the 48-hour response time of imported brands.

Working together for a shared future: a new journey of intelligent control with the new generation of industry

Devoting for over 30 years, Toky has established a high-end brand image of ’Precise, Professional, Reliable and Efficient’ in the field of industrial automation with innovation as the engine and quality as the cornerstone. The company will continue to increase investment in

Shenzhen R&D center, deepen cooperation with leading domestic research institutions, and explore the application of AI models in temperature control algorithms. Additionally, Toky will accelerate the expansion of high-end markets in Europe, North America and etc., building a

global system of ‘R&D-Production-Service’ to provide users with quality products and services.